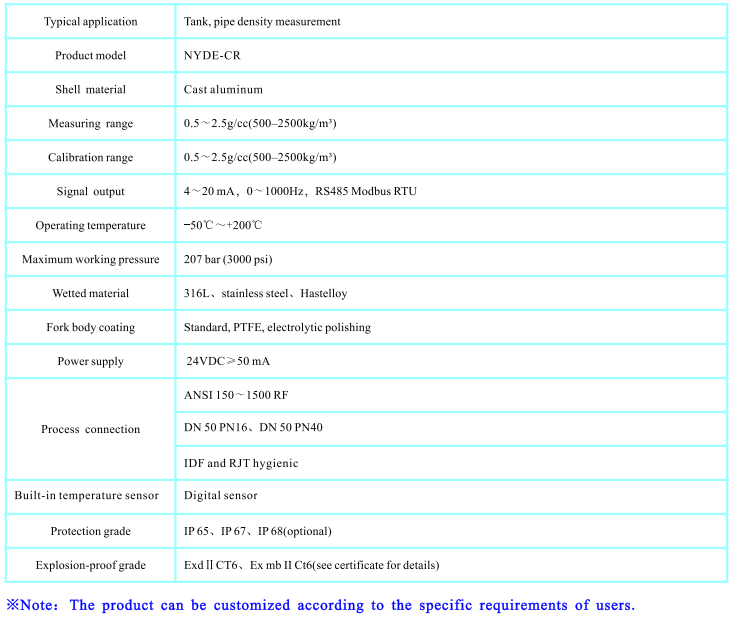

NYDE-CR type insertion density meter can perform density detection online in real time. It can be used for process control of products based on density or for quality control based on percent solids or percent concentration. With plug-in installation, it is widely used in pipelines, medium density detection in open tank containers and closed tank containers. The fluid density directly depends on the vibration frequency received by the tuning fork in the medium inserted by the sensor.

A built-in temperature sensor provides temperature compensation for it. It is widely used in petroleum, chemical, winemaking, food, pharmaceutical and mineral processing (such as clay, carbonate, silicate, etc.), and is specifically used for interface detection in multi-product pipelines in the above industries, density detection of stirred mixtures, End-point monitoring of the reaction kettle, interface detection of the separator.

Working principle

The sensor works based on the principle of component vibration, and the component part is the tuning fork part immersed in the measured liquid. The tuning fork section induces vibrations through an inherent piezoelectric device fixed to one end of the fork bottom. The oscillation frequency is detected by the secondary piezoelectric device fixed on the other end of the fork body, and then the signal is amplified by the circuit at the top. The liquid density is closely related to the vibration frequency of the liquid to be measured. , When the density of the liquid to be measured changes, the vibration frequency of the liquid will also change. Through the equation, the density of the measured liquid can be accurately calculated.

D= measured medium density without calibration(kg/m³)

T=vibration frequency (µs).

KO, K1, K2=constant

In the process of density detection, the NYDE-CR plug-in density meter can automatically compensate the influence of temperature on the density (D) of the measured medium, and the pressure has no significant influence on the density.

Design Features

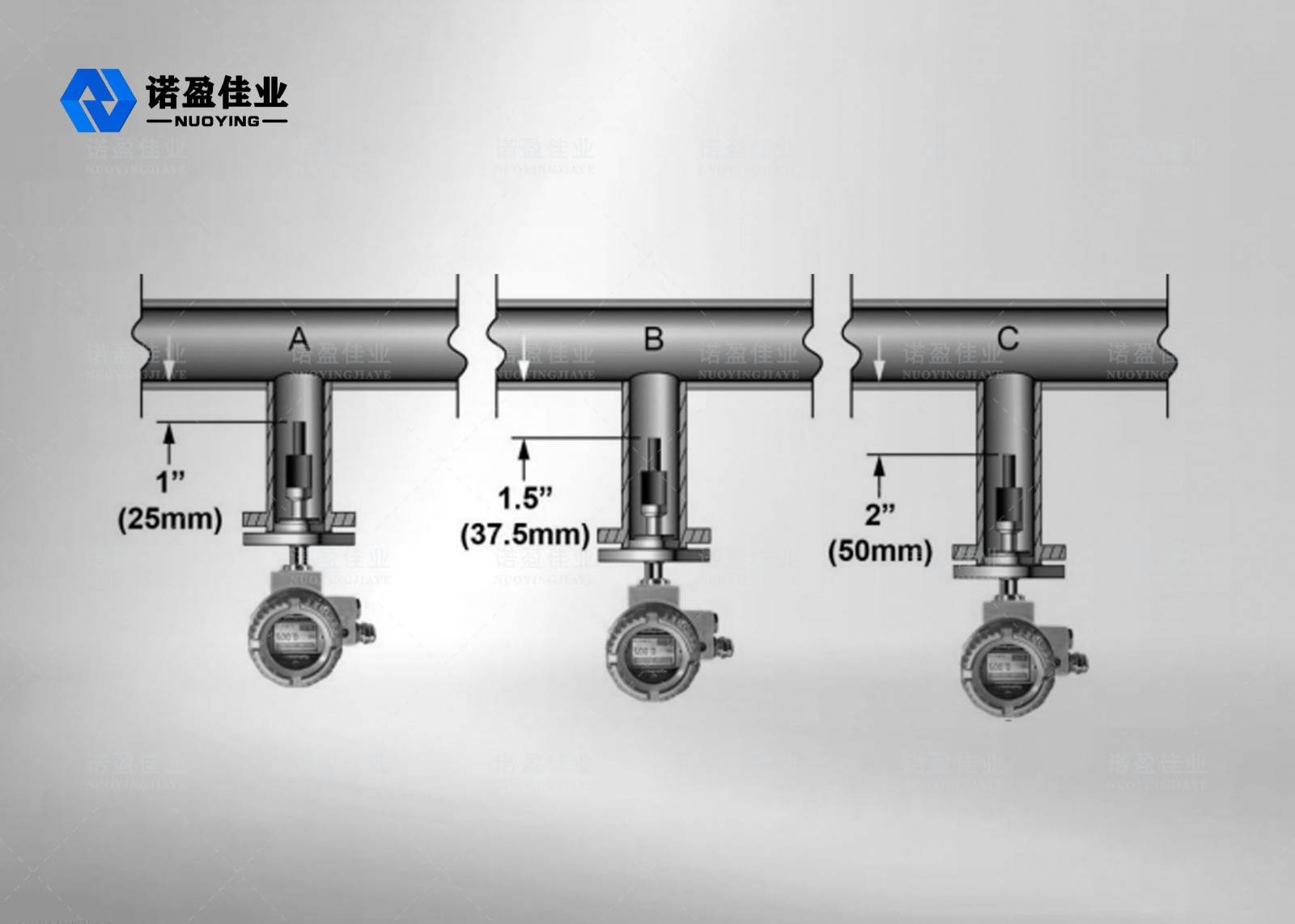

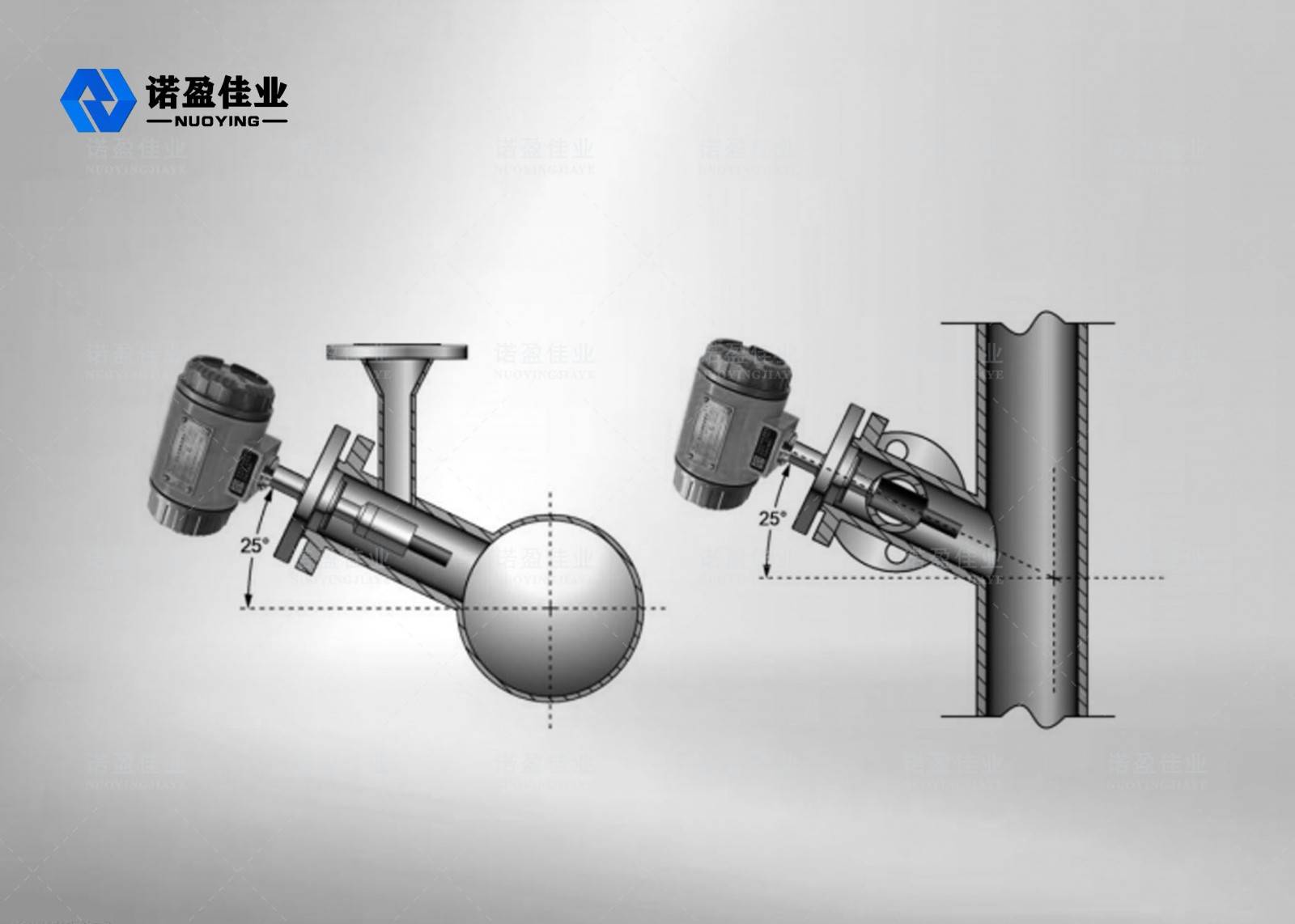

◎It is suitable for density measurement of tanks, pipes, flowing or stationary media. It is suitable for measuring high-temperature, low-temperature, and high-viscosity media with impurities.

◎Microprocessor-based electronic conversion device, which integrates signal processing, calculation and diagnostic functions.

◎Continuous online measurement of liquid density and temperature, high precision, more safe and reliable, can be directly used for production process control.

◎It can communicate directly with the PC through the RS485 interface, and the user can directly perform online node configuration, fault diagnosis and data recording.

◎While measuring density and temperature, parameters such as basic density, concentration percentage, mass percentage, and volume percentage can be calculated.

◎Excellent overvoltage protection structure, excellent temperature stability, fully welded sealing, and robust and reliable design.

◎Easy to install and use, the reading can be displayed when the liquid is inserted.

◎Simplifies maintenance and eliminates the need for regular cleaning.

◎Calibration requires no standard reference source, no laboratory calibration, and no process interruption.

◎The intrinsically safe type can be used in hazardous sites, and the hygienic type can be installed in food production sites.

Latest Demand

Latest Demand