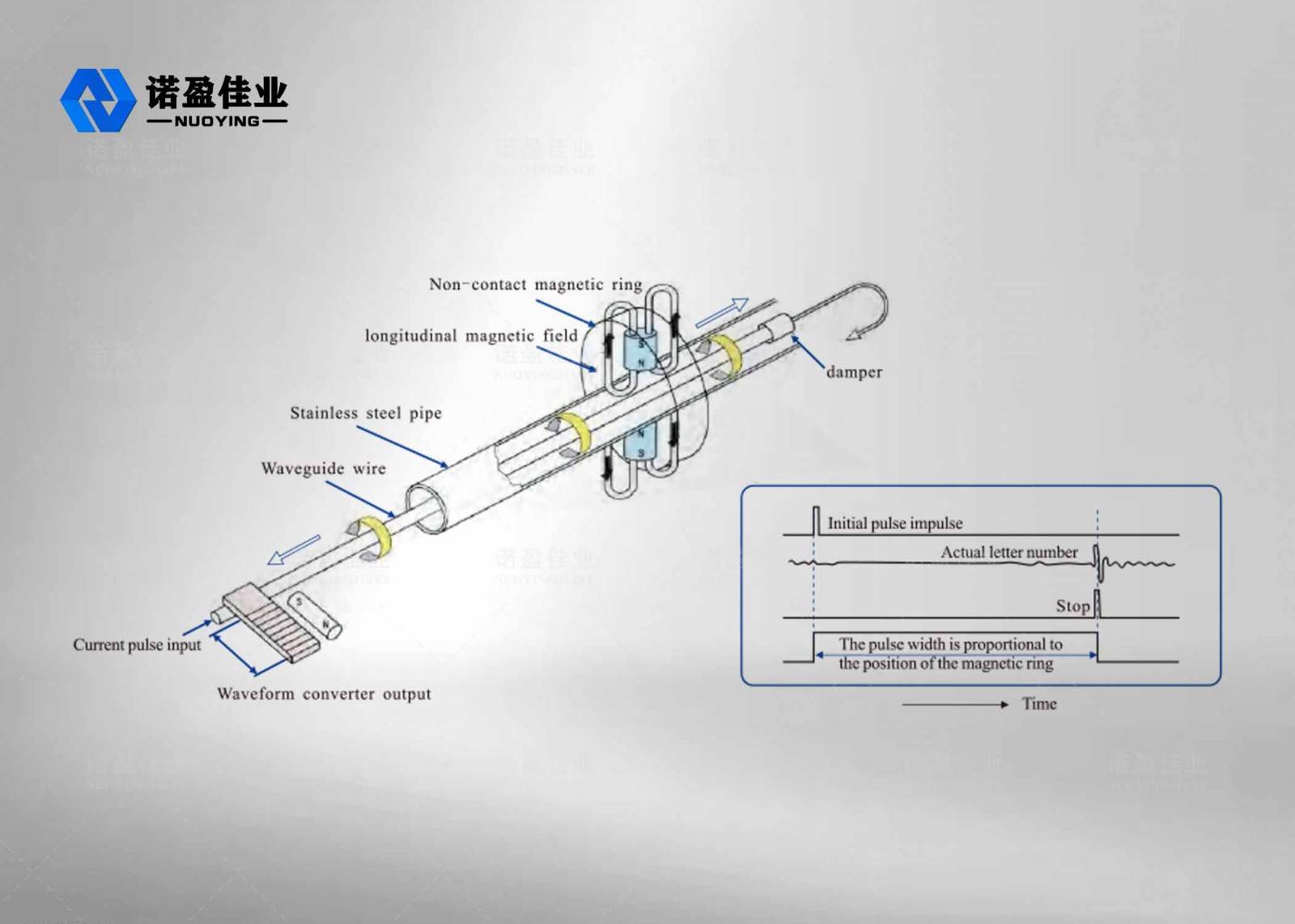

Working principle

The working principle of the magnetostrictive liquid level meter is shown in the figure. The product is mainly composed of measuring rod, electronic warehouse and non-contact floating ball set on the measuring rod. A magnetostrictive wire (waveguide wire) is installed in the measuring rod. The measuring rod is made of a non-magnetic stainless steel tube, which protects the waveguide wire very well.

When the magnetostrictive liquid level meter works, the pulse generator in the electronic warehouse sends out an initial pulse. When the initial pulse is transmitted in the waveguide wire, a rotating magnetic field is generated along the direction of the waveguide wire. When this magnetic field meets the permanent magnetic field in the floating ball, a magnetostrictive effect is produced, causing the waveguide wire to twist to generate a constant-speed mechanical wave. The mechanical wave propagates in two directions, the mechanical wave reaching the end of the measuring rod is absorbed by the damper, and the mechanical wave transmitted back to the direction of the electronic warehouse is sensed by the energy pickup mechanism installed in the electronic warehouse, and converted into corresponding current pulses, the energy pickup mechanism After calculating the time difference between the two pulses, the height of the measured liquid level can be accurately measured.

Design features

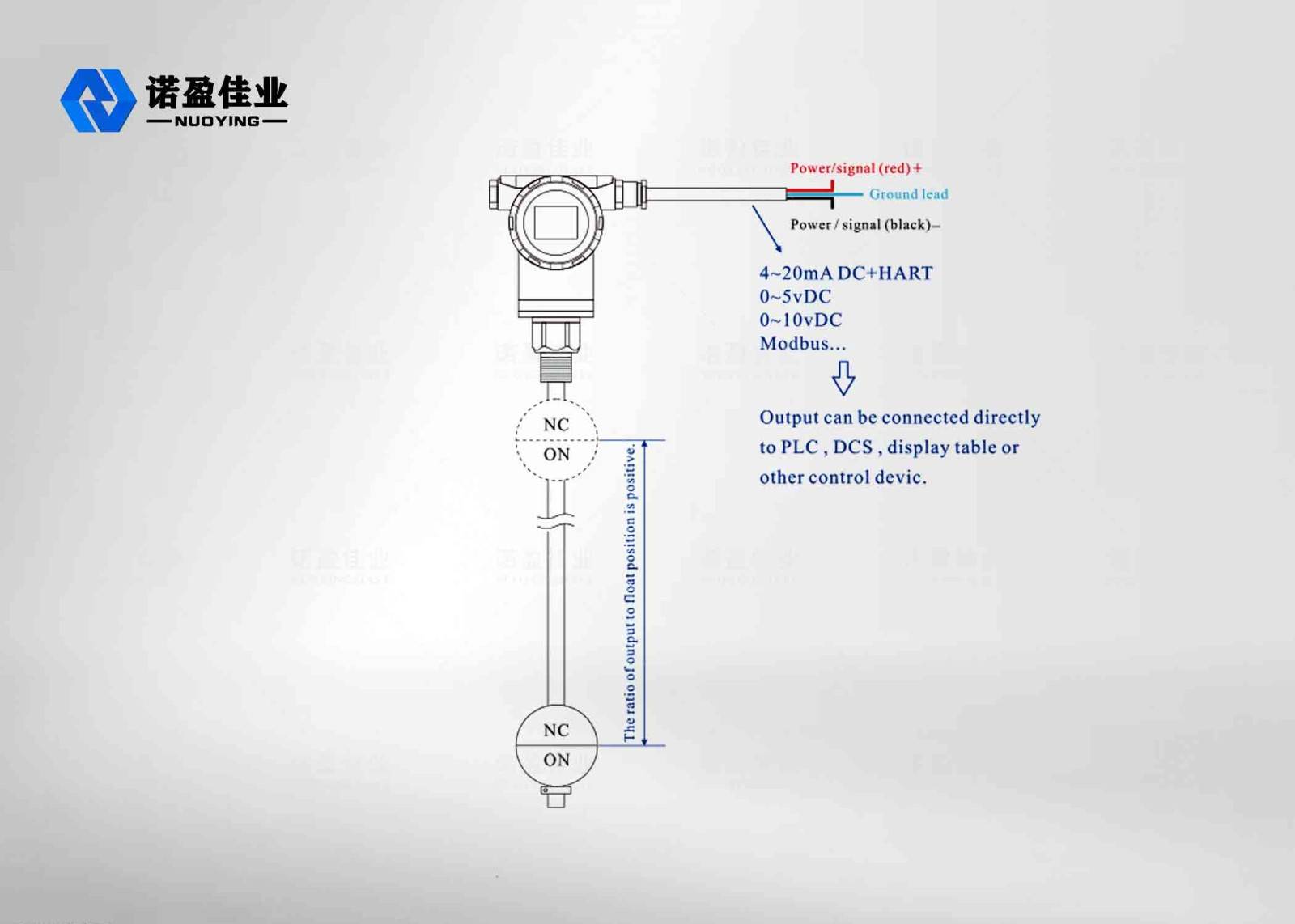

◎Wider applicability, there are various probe forms, various process connection forms, various production materials, and can be customized design;

◎Strong reliability: Because the magnetostrictive liquid level gauge adopts the waveguide principle, there is no mechanical moving part, so there is no friction and no wear. The entire converter is enclosed in a stainless steel tube, and it is non-contact with the measuring medium. The sensor works reliably and has a long service life.

◎High precision: Since the magnetostrictive level meter works with waveguide pulses, the measured displacement is determined by measuring the time of the initial pulse and the end pulse, so the measurement accuracy is high, and the resolution is better than 0.01% FS. This is an accuracy that is difficult to achieve with other sensors.

◎Good safety: The magnetostrictive liquid level meter has high explosion-proof performance, intrinsically safe explosion-proof, safe to use, especially suitable for the measurement of chemical raw materials and flammable liquids. There is no need to open the tank cover during measurement, which avoids the insecurity of manual measurement.

◎The magnetostrictive level meter is easy to install and maintain: the magnetostrictive level meter is generally installed through the existing nozzle on the top of the tank, especially suitable for the installation of underground storage tanks and storage tanks that have been put into operation, and can be installed during the installation process, also does not affect production during installation.

Latest Demand

Latest Demand