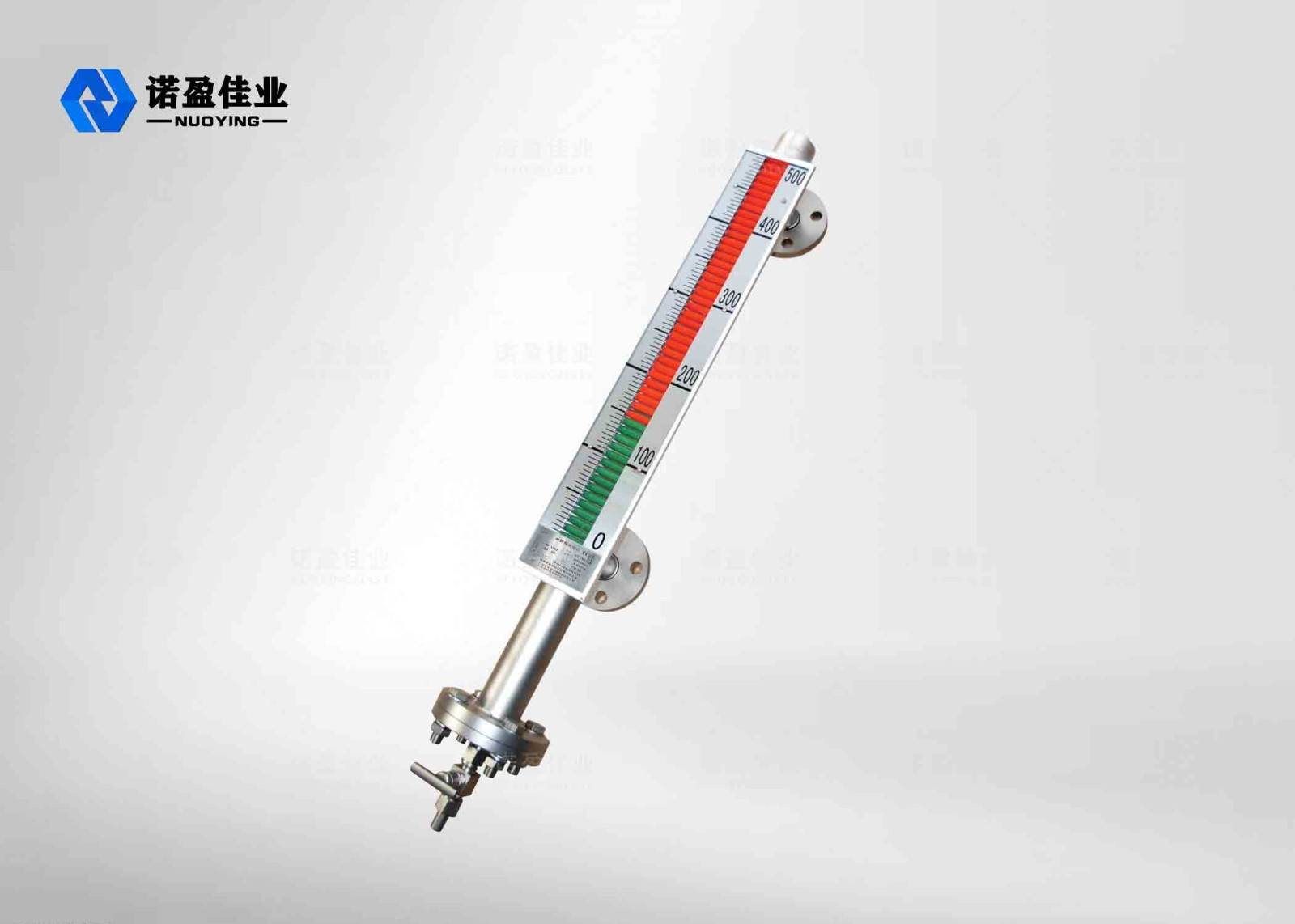

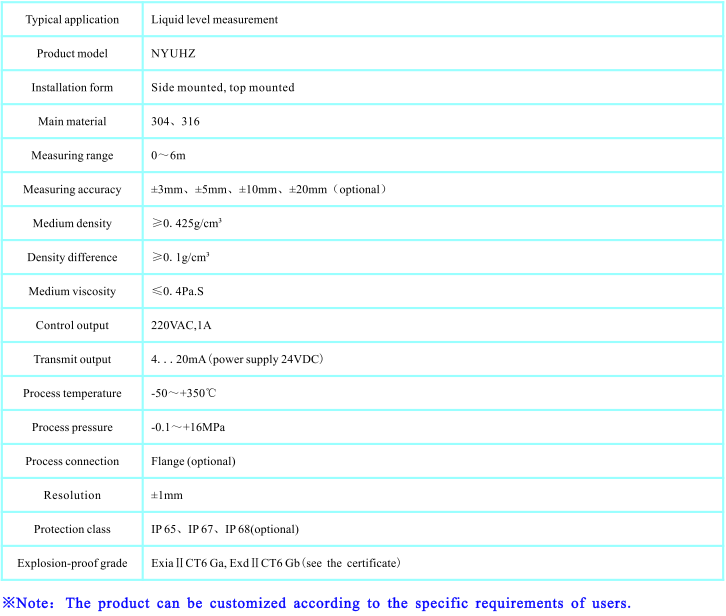

Working principle

The magnetic flap level meter can be used for medium level detection of various towers, tanks, tanks, spherical containers and boilers. Magnetic flap level meter can achieve high seal, anti-leakage and can be used in high temperature, high pressure and corrosion resistant occasions.

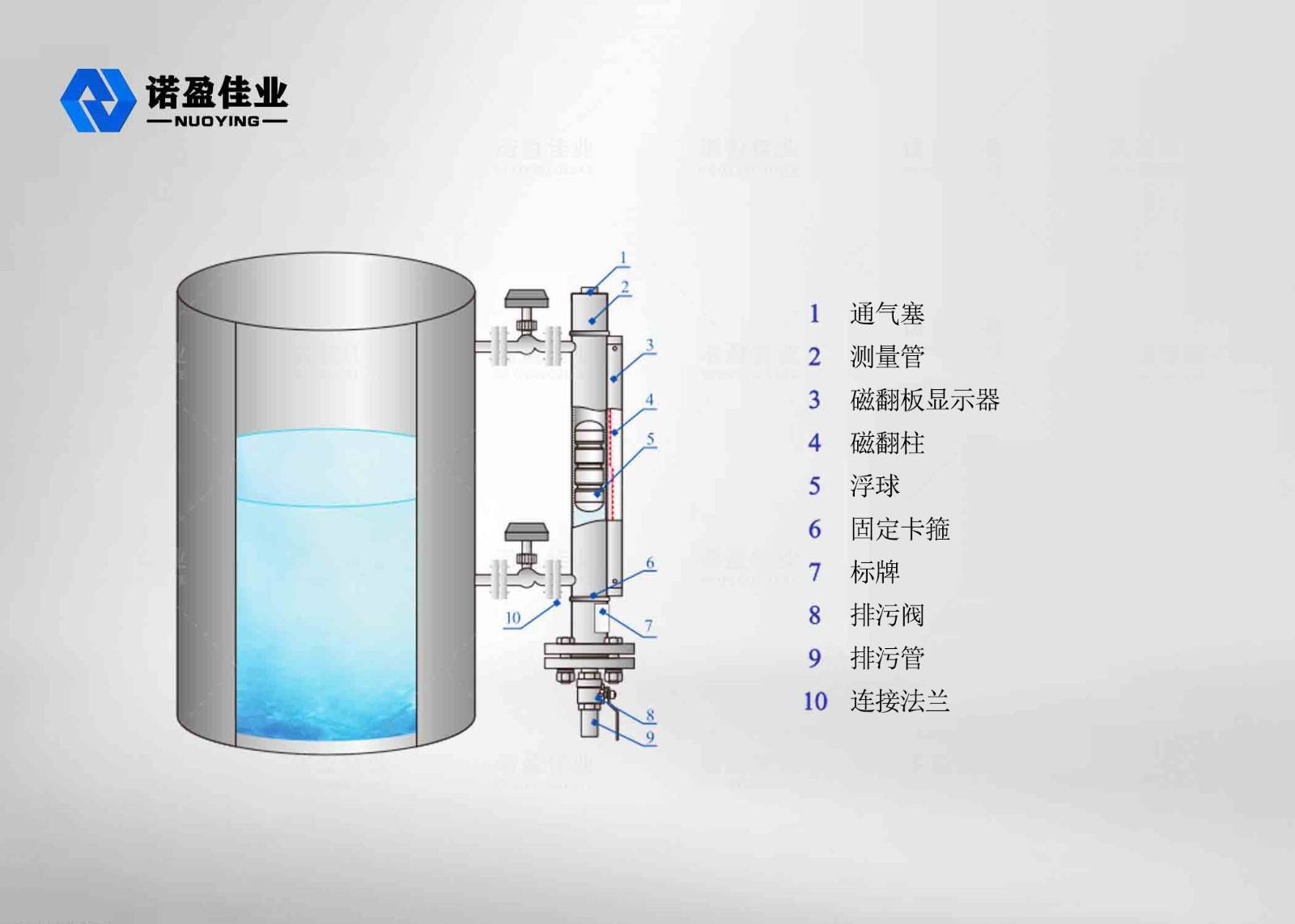

The magnetic flap liquid level meter has a cavity (called the measuring tube or the main tube) that accommodates the floating ball. The cavity forms a communication device with the container through flanges or other suitable connection methods. According to the principle of the connector, as the liquid level in the container changes up and down, the liquid level in the cavity is the same height as the liquid level in the container, so the float ball in the cavity is driven to move up and down, and the liquid level in the container rises and falls with the rise and fall of the liquid level in the container. At this time, we can't see the liquid level, so a magnetic flip column display is installed outside the cavity.

Permanent magnet steel is installed at the junction of the floating ball sinking into the liquid and the floating part. When the liquid level in the measured container rises and falls, the magnetic float in the body tube of the liquid level gauge also rises and falls, and the permanent magnet steel in the float passes through. The magnetic coupling is transmitted to the magnetic flipping column indicator, which drives the red and white flipping columns to flip 180°. When the liquid level rises, the flipping column changes from white to red, and when the liquid level drops, the flipping column changes from red to white. The junction of red and white is the actual height of the liquid level inside the container, so as to achieve a clear indication of the liquid level.

Design features

◎Simple structure, solid and reliable, stable operation.

◎The calibration is clear and easy to read.

◎Measure and indicate corrosive, inflammable, toxic, high-temperature, agitating contaminated liquid levels.

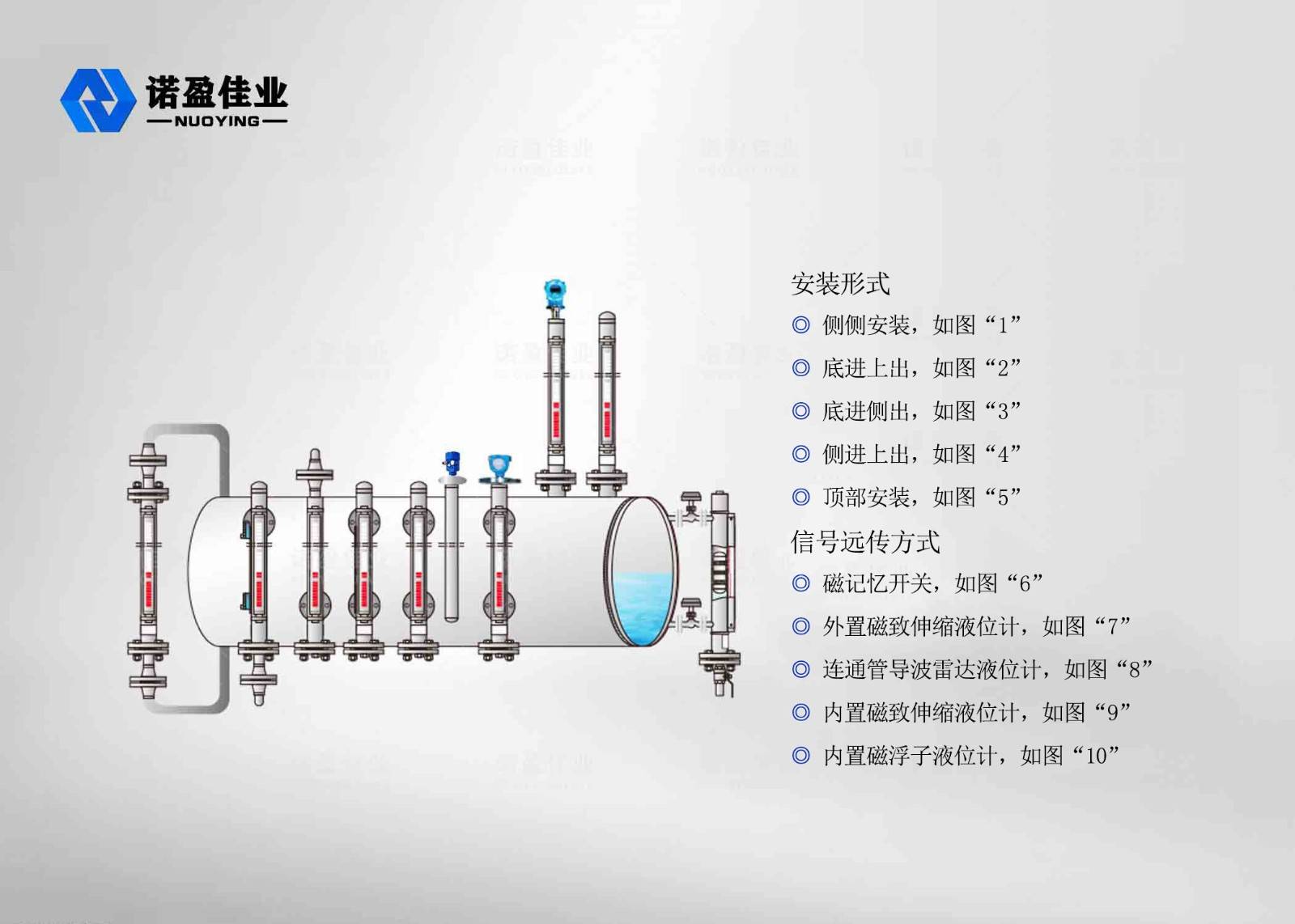

◎Multiple installation and connection modes are available.

◎Design pressure range from full vacuum to 10MPa.

◎Design temperature range -160~+450℃.

◎Professional design for special pressure and temperature.

Latest Demand

Latest Demand